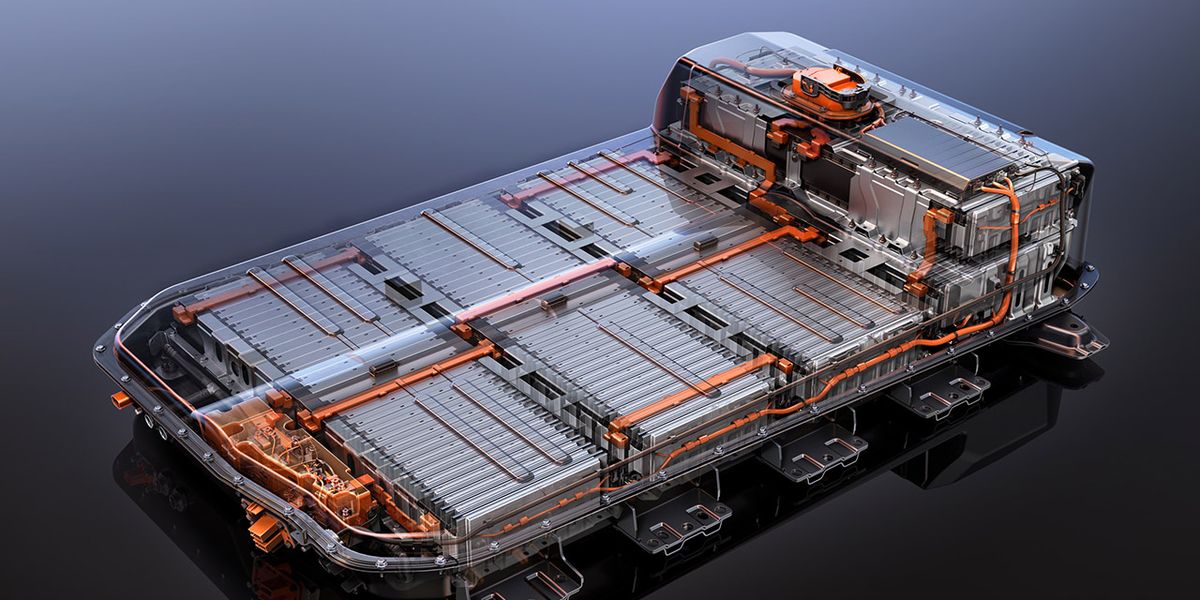

Electric cars have a battery capable of storing electrical energy that feeds one or more electric motors. If you think that there is only one type of battery, you are very wrong, we review all of them with their features and capacities.

When evaluating a battery for an electric vehicle, the following main parameters must always be taken into account:

Life cycle: These are the maximum charge and discharge cycles that the battery can withstand until it needs to be replaced. The more cycles, the longer the battery life.

Cost: the influence of the price of the vehicles.

Energy density: it is the energy that can be supplied for each kg, it is measured in Wh/kg, and the higher the density, the greater the autonomy of the vehicle.

Efficiency: It is measured in % and it is the true performance of the battery, that is to say, the energy that it uses.

Power: it is the capacity to provide power (maximum amperage), it is measured in W/kg, and more power better performance.

Next, we detail the different types of electric car batteries that are currently used:

lead-acid battery

It is the oldest of all since it was invented in the 19th century and is still alive with hardly any modifications, although it is not ideal for electric vehicles.

Specifications:

Low cost, ideal for starting, lighting, or electrical support functions.

It is used as an accumulator in small vehicles.

Excessive weight.

Lead toxicity.

Slow recharge.

They offer between 6 and 12 volts.

They can offer up to 100 km of autonomy in hybrid mechanics.

Very limited life with 500 to 800 charge and discharge cycles.

Very low energy density.

It requires periodic maintenance.

Nickel-cadmium battery

The high cost of its components means that it is not the majority solution in the manufacture of electric vehicles, which is why it is more oriented toward airplanes, military vehicles, and helicopters, due to its great performance at low temperatures. It is used only in electrified vehicles.:

They have a memory effect, so their capacity is reduced with each recharge.

Remarkable useful life, with 500 to 2,000 charge and discharge cycles.

Limited energy density.

It requires some care and maintenance.

Quite a high price.

High temperatures cause them to degrade precipitously.

Quite polluting.

Limited technical capabilities.

Nickel-iron battery

Patented in 1903 and developed by Thomas Edison, they are currently mounted only in vehicles of low power and efficiency, although they have an energy density similar to that of lead acid.

Nickel metal hydride battery

Similar to nickel-cadmium, but with better capacity and less environmental aggression, which is why it is well accepted among hybrid vehicles.

They require constant maintenance.

Significant deterioration at high temperatures.

High discharge currents or overloads, but they do not withstand strong energy discharges or high charging currents.

They generate too much heat and recharge slowly.

Lifetime limited with 300 to 500 charge and discharge cycles.

Interesting energy density.

Lithium-ion battery (LiCoO2)

They are currently preferred by electric automobiles due to their high specific energies, high efficiency, the elimination of the memory effect, lack of maintenance, and ease of recycling Lithium-Ion waste, although they are still in the development process.

Twice the energy density of nickel-cadmium batteries, with a size on the order of a third smaller.

They offer good autonomy.

High production cost, although little by little this is being reduced.

They are fragile.

They can explode from overheating and must be stored with great care.

Good levels of useful life with 400 to 1,200 charge and discharge cycles.

They do not require any type of maintenance.

Quite a high-security level, although they require a specific security circuit.

The main current variants of lithium-ion batteries are:

LiFePO4 battery

It does not use cobalt so it has greater stability and safety. It provides a longer life cycle and higher power, although with lower energy density and at a high-cost today.

lithium polymer battery

It has some improvements such as a higher energy density and a higher power. They are lighter, more efficient, and have no memory effect. Its high cost and low life cycle give these batteries, a “soft” appearance due to their lithium and polymer components, an option that is not currently very widespread.

NCM Battery

It is a lithium-ion battery, but with its cathode made up of nickel-manganese-cobalt, it achieves good values of energy density, thus allowing the sale of slightly cheaper electric cars, and with good autonomy.

NCA Battery

In this case, its cathode is made of nickel-cobalt-aluminium, achieving excellent energy density and very good charging efficiency, but with somewhat lower performance at high temperatures.

solid state battery

It is also an evolution of the lithium-ion battery and has an electrolyte that is not a conductive liquid, but rather a solid conductor, thus drastically reducing its degradation over time, with a much longer useful life. They are the ‘great evolution’ within the different types of batteries for electric cars.

ZEBRA battery (molten salt)

They have crushed sodium chloroaluminate as an electrolyte, achieving very interesting energy and power characteristics. They have the best cycle life of all batteries, but they take up a lot of space and their power is low.

Aluminum-air battery

With a storage capacity of up to 10 times more than the Lithium-Ion type and an energy density beyond the reach of the rest, this type of battery has not had a good commercial acceptance due to its recharging and reliability problems. It is in the experimental phase.

Zinc-Air battery

Also in the experimental phase, they need to obtain oxygen from the atmosphere to generate a current. It has a high energy potential, and reliability and is capable of storing three times the energy of lithium-ion batteries in the same volume and at half the cost. According to some experts, zinc is positioned as the electrical fuel of the future.

The post Types Of Battery For Electric Car appeared first on Schmicko Mobile Car Detailing & Car Care.